We are sometimes asked about geometric tolerances. While Tolcap gives sound estimates of

process capability for straightforward tolerances, this is because we have extensive series

production data for the maps we publish. We don’t have such data for geometric tolerances such

as flatness, roundness, etc., so we won’t compromise the Tolcap data base by publishing maps for

them.

We are sorry we cannot publish maps for positional tolerancing, because that is fundamental to

geometric dimensional tolerancing (GDT) and the ‘maximum material condition’ problem

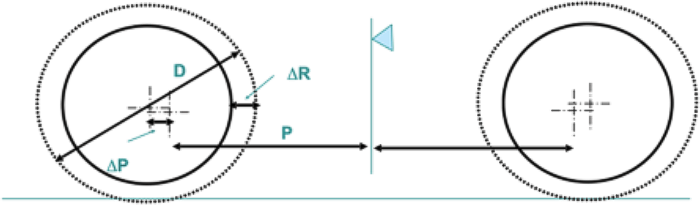

To explain this problem, suppose you have one part with two studs which are to fit into two holes

in another part. How do you dimension and tolerance the parts? In the maximum material

condition, the holes are at their smallest and the studs at their largest. Think of the outside

dimensions of the studs and holes: the maximum distance apart of the centres of the studs plus the

maximum diameter of the studs must be less than the minimum distance apart of the centres of the

holes plus the minimum diameter of the holes. But at the same time, think of the inside

dimensions: the minimum distance apart of the centres of the studs minus the maximum diameter

of the studs must be greater than the maximum distance apart of the centres of the holes minus

the minimum diameter of the holes. OK, the nominal distance apart of the holes should be

specified the same for both parts, but the difference in the nominal diameters of the holes must

accommodate the range in the tolerance stack up. The stack up comes down to the tolerance on

the hole or stud diameters and the positional tolerance or distance between the centres. Tolcap

can help with the diameters, and maybe provide a solution for the studs * (see below) - but we

don’t yet have the data for a positional tolerance map to apply to the holes.

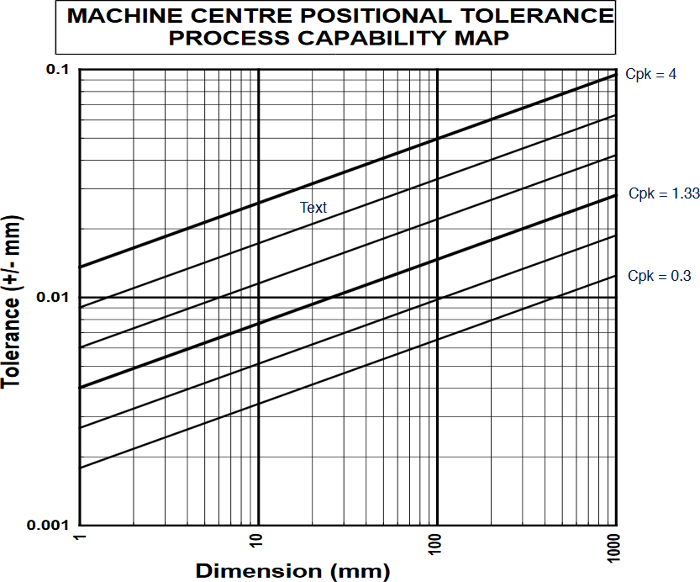

We have a start: the map here reflects our best shot at the machining centre positional tolerance

considering just the repeatability of a machine tool moving from one centre to another. (This has

been published: see

K.G.Swift & J.D.Booker Process Selection from Design to Manufacture,

Butterworth Heinemann 2003, page 138 in this second edition.

)

What we don’t have is data on other factors, such as the ‘jump’ or jitter when the cutting tool (drill)

meets the surface of the part.

We have algorithms for generating maps from data of course, and this is a case where we would

be delighted to work with our clients who could provide data to generate a positional tolerance

map.

* I said Tolcap might provide a solution for the studs: if the studs were cast or milled, then we could

use Tolcap to find the capable tolerance for the outside dimension of the studs, for the inside

dimension we could then find capable tolerances for the diameters and from these the positional

tolerance for the centres. It depends on the manufacturing process. The problem area is the

positional tolerance of the centres of the holes.

Written by:

Richard Batchelor MA, MBA, CEng, FIEE

Richard is a founding member of the Capra Technology team.