We are sometimes asked to extend the scope of Tolcap, and one particular recurring request is that we address a much

wider range of plastics for injection mouldings. It has been an issue that we pride ourselves that all our maps

are based on empirical data: - as they say: ‘Never trust a statistic you haven’t manipulated yourself!’

That question was raised again recently, but this time the enquirer pointed us to standards for plastic parts,

including DIN 16901, ‘Plastics Mouldings; Tolerance and Acceptance Conditions for Linear Dimensions.’

The standard does indeed list many different plastics, and it puts them in a table showing tolerance groups.

Tighter tolerances may be specified for some materials than for others. Now we have used international standards as

well as directly collected data for the maps in Tolcap, because they clearly incorporate a mass of knowledge by

skilled manufacturers, and such standards will therefore naturally reflect process capability.

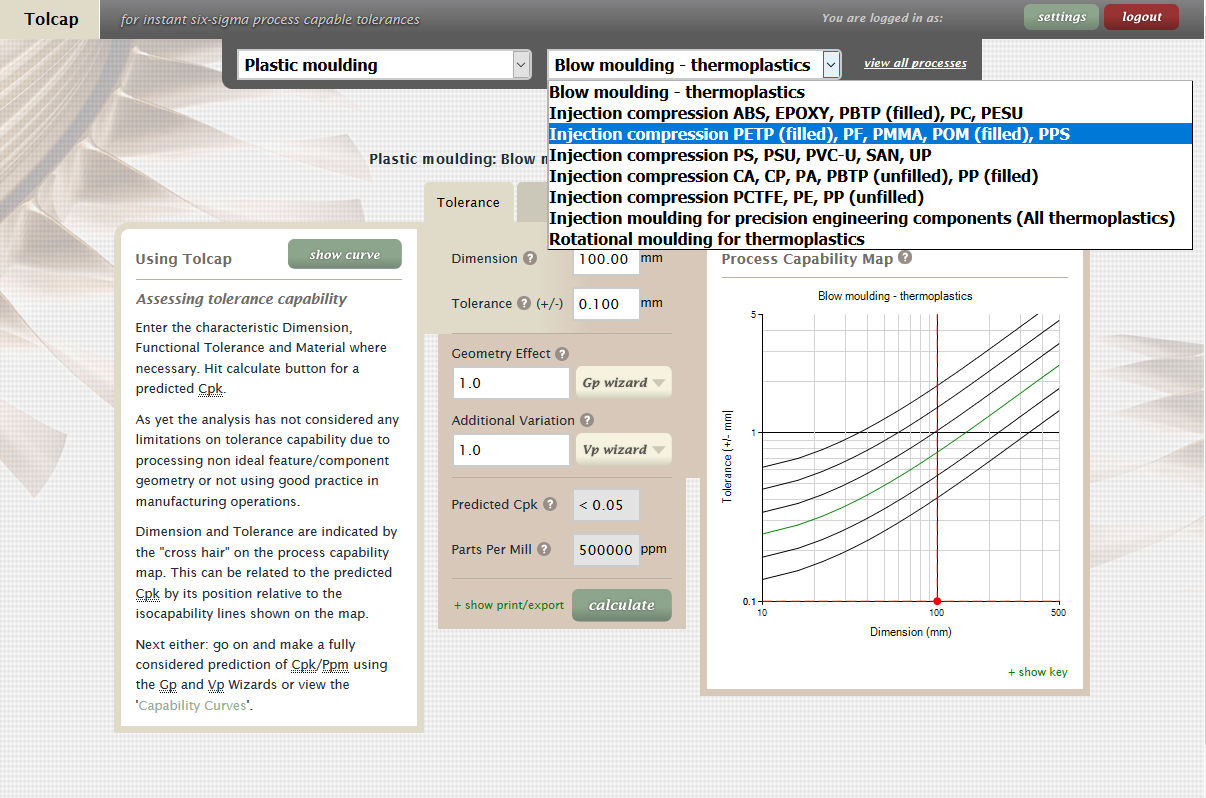

We looked at the table in DIN 16901 and sorted it by tolerance groups. We then looked at our various maps for plastic

injection moulding. They are material specific:

figure 1.

- PETP (filled), PF, PMMA, POM (filled), PPS

- CA, CP, PA, PBTP (unfilled), PP (filled)

- ABS, EPOXY, PBTP (filled), PC, PESU

- PS, PSU, PVC-U, SAN, UP

- PCTFE, PE, PP (unfilled)

Looking at the standard to see which tolerance groups are appropriate to these materials, we find that all of the materials in each map relate to the same tolerance group:

Map Materials Tolerance Group:

- PETP (filled), PF, PMMA, POM (filled), PPS 130 120 110

- CA, CP, PA, PBTP (unfilled), PP (filled) 140 130 120

- ABS, EPOXY, PBTP (filled), PC, PESU 130 120 110

- PS, PSU, PVC-U, SAN, UP 130 120 110

- PCTFE, PE, PP (unfilled) 150 140 130

We then looked at the maps for each group and compared the Cpk = 1.33 tolerance at each of the main axis dimensions:

1mm, 10mm, 100mm, 1000mm:

Groups 1, 3, 4 have the tightest tolerances, identical at dimensions 1, 10, 100, 1000.

The spread of the lines of equal Cpk and the shape of the curves of the maps are very similar. They are effectively the same map;

Group 2 tolerances are all increased over groups 1, 3, 4;

and Group 5 tolerances are all increased over Group 2.

Such close correlation between the Tolcap curves and DIN 16901 tolerance groupings gives us the confidence to propose

that the maps we have generated based on the subset of materials from each tolerance group for which we happened

to get data may be applied to any other material in the same tolerance group in DIN 16901.

Due diligence is required, but we can be pretty sure this is a really useful expansion of Tolcap.

Our confidence stems from the point we made in the YouTube videos - Tolcap can’t be accurate to three places of decimals,

nor does it need to be - it just needs to be sufficiently accurate to be plausible. We know it is pretty good, and a

customer can give a drawing to a supplier and say that there is a tool that predicts all the tolerances will be Cpk = 1.33

(oh, and maybe there are a couple that are Cpk = 1.0 and are marked as special). The supplier then has numbers to look

at and can either accept that he should achieve Cpk = 1.33 or can disagree - but then the answer lies in real process data

from existing parts or test pieces. The extension of the map is plausible - and we welcome any feedback data from any

user who finds exceptions for any specific material.

In summary we recommend that Tolcap can be applied to most materials listed in DIN 16901 by using our map applicable

to the same tolerance group.

So:

| For plastic types | Use the Tolcap map for |

|---|

| EP | ABS, EPOXY, PBTP (filled), PC, PESU |

| UF/MF (with inorganic fillers, types 155, 156, 158) |

| ASA |

| PA (amorphous or glass reinforced) |

| PDAP |

| PPO |

| SB |

| Mixtures of Polyphenelene oxide & Polystyrene... |

| For plastic types | Use the Tolcap map for |

|---|

| EVA | CA, CP, PA, PBTP (unfilled), PP (filled) |

| PF(with organic fillers) |

| UF/MF (with organic fillers & types 157, 182, 183) |

| UP |

| Cold moulding compounds (type 212, 214) |

| CAB |

| CAP |

| PETP (crystalline) |

| POM (without filler, moulding length < 150mm) |

| PP/EPDM (mixture of PP & rubber) |

| For plastic types | Use the Tolcap map for |

|---|

| POM (without filler, moulding length > 150mm) | Use Tolcap map for PCTFE, PE, PP (unfilled) |

Written by:

Richard Batchelor MA, MBA, CEng, FIEE

Richard is a founding member of the Capra Technology team.

Related blogs

‘The Tolcap Rough Guide to Tolerancing Plastic Mouldings’ series (Dec 2019):